Upstream operations demand absolute reliability. Extreme pressure, corrosive fluids, and limited space leave no room for failure - a single leak can cost millions or worse. Backed by decades of oil and gas experience, Parker delivers proven solutions to maintain uptime, protect assets, and ensure safe, efficient operation in unforgiving conditions.

Solutions Built by Function

Explore Parker's upstream capabilities across key operational areas, designed to tackle your toughest field challenges.

Measurement & Monitoring

Capture stable, accurate data under vibration, pressure, and corrosion, ensuring safe, real-time decision making.

Flow & Pressure Control

Enable reliable actuation and flow control with components built for high loads and hostile environments.

Isolation & Safety

Protect personnel and equipment with compact valve solutions that reduce emissions and support safe access.

Sampling & Injection

Maintain production integrity through precise dosing, efficient sampling, and backflow prevention in critical systems.

Measurement & Monitoring

Accurate pressure, flow, and temperature data is essential for safe, optimised upstream operations. Yet vibration, space constraints, and corrosive media increase the risk of leaks and fugitive emissions. Parker's compact, high-integrity valves and manifolds maintain system accuracy and integrity under pressure, supporting reliable data acquisition, calibration, and reduced leak paths in the harshest conditions.

White Paper

The Power of Quality

Avoid costly delays and quality issues when sourcing critical materials like 6Mo and Alloy 625. Learn how Parker ensures traceability, availability, and long-term performance in demanding oil and gas environments.

Flow & Pressure Control

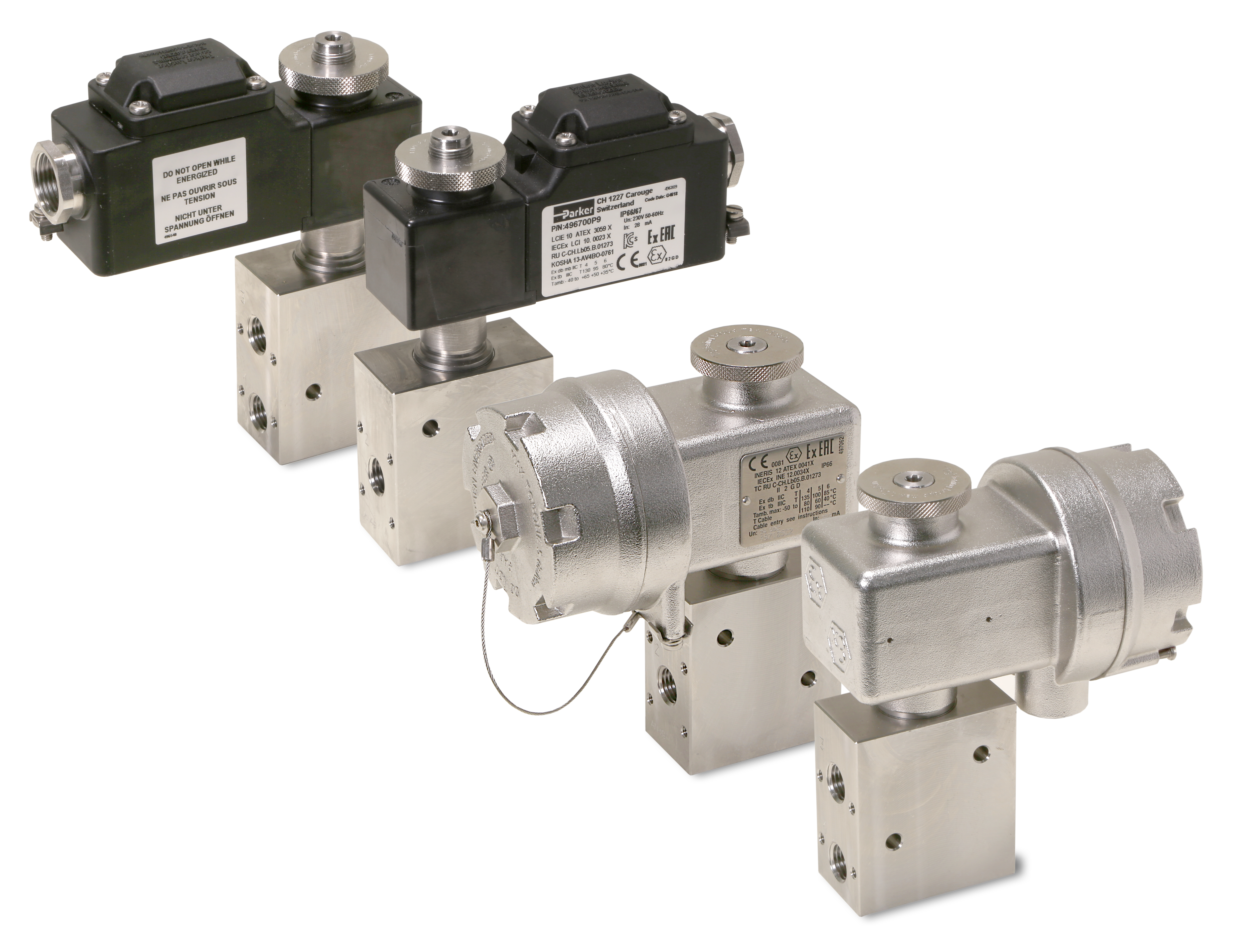

Precise flow and pressure control is critical to safe and efficient upstream operations - from managing wellhead safety systems to operating hydraulic actuators and emergency shutdown devices. With limited space, hazardous area requirements, and extreme pressure demands, every component must deliver reliable, leak-tight performance. Parker's solenoid valves, fire-rated hoses, compact manifolds, and tube & fttings are engineered to ensure fast response, maximum safety, and robust control in the most demanding conditions.

Need Help?

Can't Find What You're Looking For? Get in Touch With One of Experts

Isolation & Safety

Safe isolation is vital for upstream maintenance, pressure containment, and emergency response. With high operating pressures, sour media, and space-constraints, reducing leak paths and simplifying actuation is essential. Parker's valves with integral end connections, corrosion-resistant fittings, and certified solenoid valves enable operators to isolate systems safely, reduce emissions, and minimise operational risk in demanding offshore and onshore environments.

VIDEO

10 Steps to Leak-Free Connections

Discover how fully integrated tubing and valve assemblies eliminate unnecessary connections and leak paths. Watch our short video to learn how to improve safety, efficiency, and cost performance across your instrumentation systems.

Sampling & Injection

Accurate chemical injection and representative sampling are essential for maintaining flow assurance and process integrity. In upstream environments where pressure is high, space is limited, and contamination risks are real, precision matters. Parker's modular injection valves, sampling conditioning systems, and high pressure hoses deliver safe, efficient fluid transfer and reliable backflow protection -minimising leak paths, umbilical bulk, and unplanned downtime.

Why Choose Parker for Upstream Applications

Materials Sourced for Harsh Conditions

Parker components are engineered from high-performance, corrosion-resistant alloys to meet the demands of aggressive upstream environments - including sour gas, high pressure, and subsea exposure. Materials such as 6Mo, Alloy 625, Alloy 825, and Titanium ensure long-term reliability under chemical attack, temperature extremes, and mechanical stress. Every material is fully traceable and compliant with offshore durability and safety standards.

Compact, Field-Proven Designs

Space and weight matter in upstream operations. Parker's valves, manifolds, and hoses are compact by design - reducing system footprint, simplifying layout on skids and wellheads, and cutting leak points. validated on offshore platforms, FPSOs, and remote wellsites, these rugged components are engineered to simplify installation and ensure uptime in hard-to-reach locations.

Compliance with Global Standards

Parker's upstream instrumentation and flow control portfolio is designed to meet or exceed leading global standards, including API, NACE MR0175/ISO 15156, PED, ATEX, and ISO 15848. Whether it's chemical injection, hazardous area valves, or fire-safe systems, Parker helps ensure full compliance with industry regulations and internal engineering specifications.

Global Capital Projects Support

Parker supports large-scale oil and gas developments worldwide with a dedicated capital projects team. From FEED to commissioning and beyond, we help manage complex specifications, documentation, and delivery schedules. With a proven history of executing exceeding multi-million-dollar packages for major producers, Parker ensures high-volume supply - on time, to spec, and anywhere on the map.

Related Content

Materials Selection: Choosing the Right Mix to Prevent Corrosion

ARTICLE

Learn how proper material selection mitigates risk in extreme upstream environments.

High-Pressure Hoses

VIDEO

Parker's high-pressure hoses are raising the bar for safety, reliability and innovation. From equipment conception to the drilling platform, Parker provides cutting-edge hoses engineered to replace old technology.

Small Bore Expert Training

This course equips fitters, technicians, and maintenance personnel with the essential knowledge and practical skills to safely install and maintain small bore tubing systems. Emphasis is placed on achieving long-term system integrity, efficiency, and leak-free performance.

Save Space and Cut Weight with Compact Manifolds

VIDEO

Achieve up to 40% length and 20% weight savings with Parker's new Hi-Pro distribution manifolds.

Thermoplastic Hoses Catalogue

Autoclave Engineers Catalogue

Process-to-Instrument & Piping Valves Catalogue

Solenoid Valves Catalogue

Need Help?