Liquid-Dispense Cure in Place Gap Fillers Up-Close

Liquid-dispense gap fillers can be applied in a variety of patterns to achieve your most challenging electric vehicle designs. Watch our video of them being dispensed through MMD equipment.

Battery Packs

Applications: Cell to Cooling Plate, Cell to Module, Module to Pack

As battery technology evolves towards increased energy density, the ability to manage heat during charge and discharge cycles is crucial for optimizing performance. Our CoolTherm thermal management materials are fully customizable and compatible with cylindrical, pouch and prismatic battery cells. Our dedicated application engineers will work with you to ensure your project’s specific performance requirements, cost targets and deadlines are met quickly.

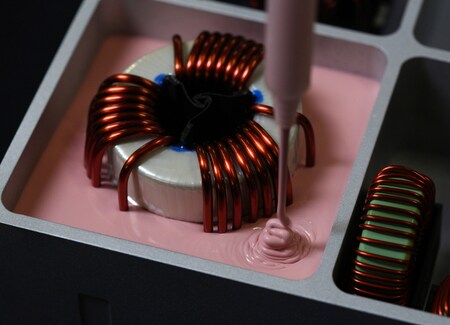

Charging Systems

Applications: Inverter, Converter, Charging Handles

CoolTherm solutions improve proper heat flow in inductors and transformers, optimize performance during charging and discharging, and increase product longevity. Since these products have a low viscosity, they flow easily into the tiniest crevices, enabling better impregnation of irregularly-shaped magnetic components and helping to reduce inductor hum. We can help you select the correct material and optimize your process to improve performance and lower costs.

Power Electronics

Protect components and improve stability - in order to extend the life of your power electronics, you need to maintain low thermal resistance and protect components from shock, moisture, and debris. CoolTherm products are robust thermal interface materials that protect delicate electrical components and provide excellent isolation and vibration dampening.

Infotainment Devices

Infotainment devices are the main source of information for EV drivers when it comes to entertainment, navigation, feedback from the vehicle, cabin comfort, and more. Since there are so many small electronics housed behind one screen, it's important these circuit boards stay cool, especially when packed into a tight space.

Focus on Quality

Expect the Same Level Quality Around the Globe

We provide products and services that consistently meet customer expectations of quality and value. A central element of our culture is an unwavering commitment to quality and continuous improvement. Our thermal management team is certified and registered to ISO 9001 and IATF 16949 which guides our focus on producing the highest quality products.

Not sure which product you need? Talk with one of our experts.

Resources

Product Catalog: Microelectronics

Explore our microelectronics solutions. If you need help choosing one of our standard microelectronic products or if they don’t quite meet your needs, let us help you determine an appropriate solution for your application.

Product Catalog: Potting & Encapsulation

We offer potting & encapsulants that are thermally conductive for applications where you need to remove heat, as well as non-thermally conductive materials.

Blogs

Gap Fillers for Thermal Management: Part One

Increased density means more heat is being created in smaller volumes, making thermal management a vital issue for battery pack performance and design.

What are Gap Fillers?

Battery performance is crucial to the continued advancement of electric vehicle (EV) design. One of the fundamental challenges in creating a battery pack is the effective management of heat generated during the battery’s charge and discharge cycles. Learn about how gap fillers aid in the removal of heat.