Getting a charge out of composite aircraft

The increasing use of composite materials in aircraft design brings many advantages but also a key challenge: the need to address lightning strikesand their effecton this type of aircraft. Our lightning protection equipment powerfully dissipates the static chargecaused by such strikes and other elctrical conditions, thoroughly solving this problem.

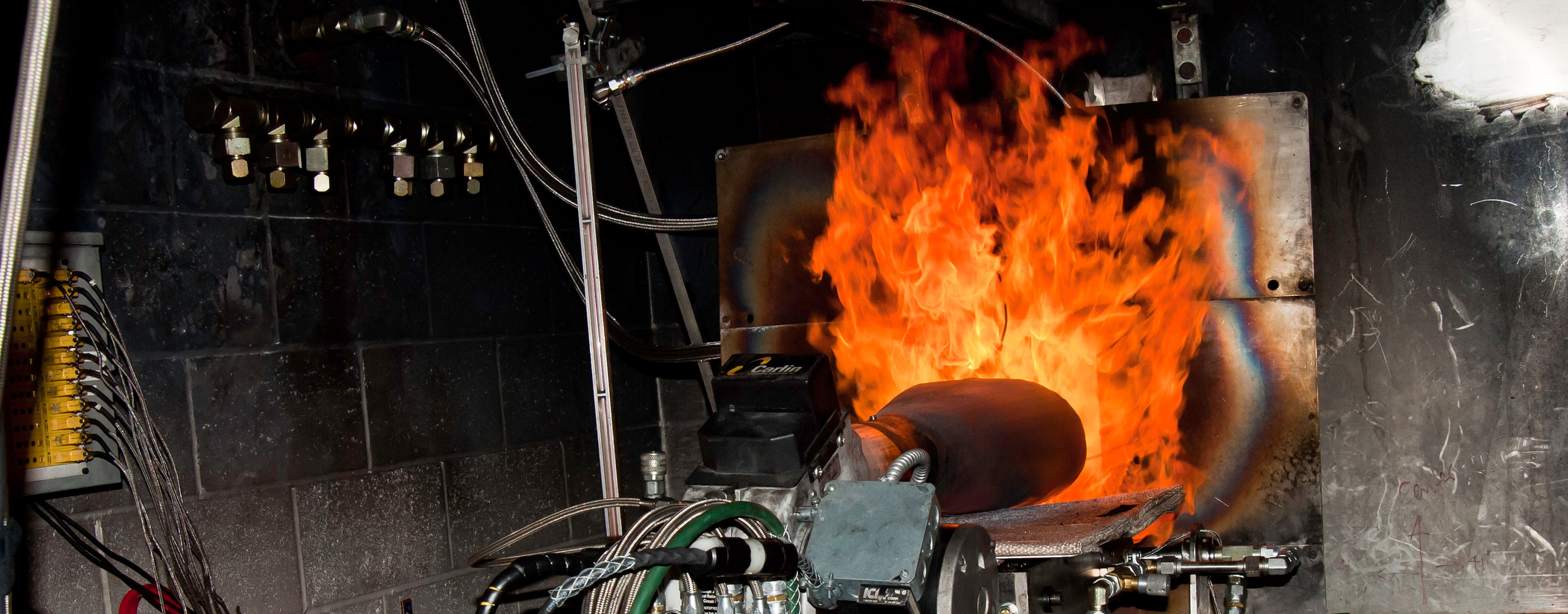

With specialized lightning test capabilities, Parker provides advanced protection and reliability. Lightning testing meets stringent requirements for MIL-STD-1757; FAA AC-20-53A, RTCA; and D0-160D, Sct 23 ARP 5412..

Lightning testing can be run for the following: up to 200 kiloamperes oscillatory current waveform (components A, Ah, and D); up to 3,000 amperes unipolar current waveform (component B); photographic and explosive mixture ignition detection; over 2,500 mf at 5,000 volts, and over 60 mf at 45,000 volts.

Reliable lightning protection equipment and safety certification confidence

Our array of Lightning Safe® products has been designed to meet and often exceed the stringent lightning safety requirements of the aircraft industry. We are proud to have over 3,000 active, certified parts, including patented Lightning Safe® fuel caps and adapters.

Parker's lightweight, high-pressure isolator (or highly resistive union) provides lightning protection for the entire life of an aircraft, avoiding the risk of fire and serious safety incidents. It is the only long-life solution available on the market.

Our factory transformation expedites production and delivery of these crucial parts, and offers full mechanical in-house assembly, all in our 132,000 sq.ft. manufacturing facility. We also make it a top priority to continually invest in the latest processes, tools, and testing equipment.

- <p>Composite materials for aircraft wing structure are increasing the need for lightning protection equipment</p>

- <p>Aircraft composite material application background, evolution, and lightning strike mitigation equipment</p>